-

Posts

191 -

Joined

-

Last visited

Content Type

Profiles

Forums

Prizes

MSUK-Forum - RC Model News and Community

Articles

Events

Posts posted by fornowagain

-

-

If you have the tools. You could drill and tap the end of the dog and use a grub screw to clamp the pin.

-

Wow...so glad I didn't buy one of these!!!

I'm glad I did, the kit anyway. Be aware of a few issues as you build it to avoid problems and it rocks. One of the most fun RC's I've ever owned.

-

-

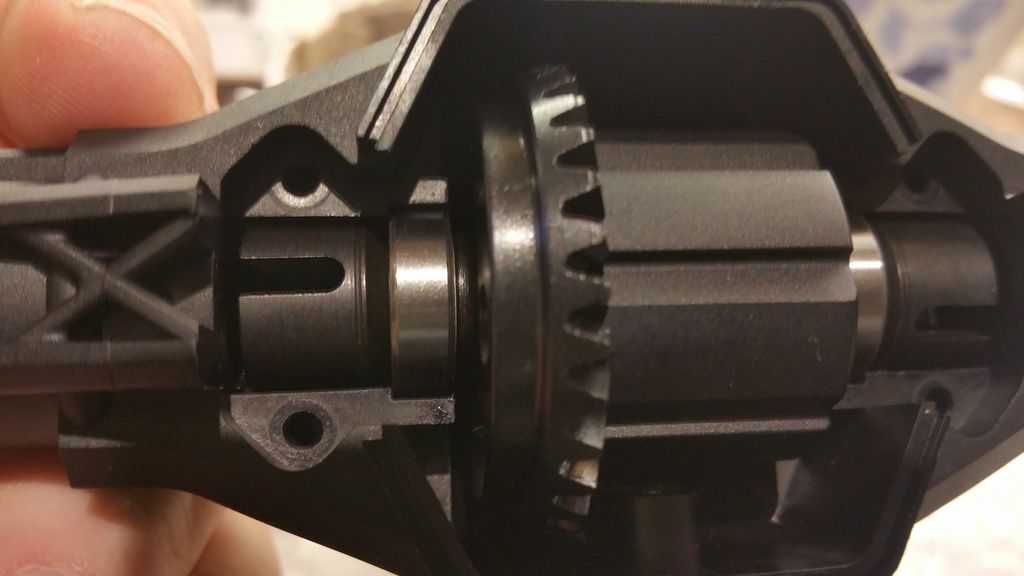

That is the standard spur.

-

Me too, can't say I've seen any for sale from HK. Last time I bought one was a chunk of change from a US breaker.

-

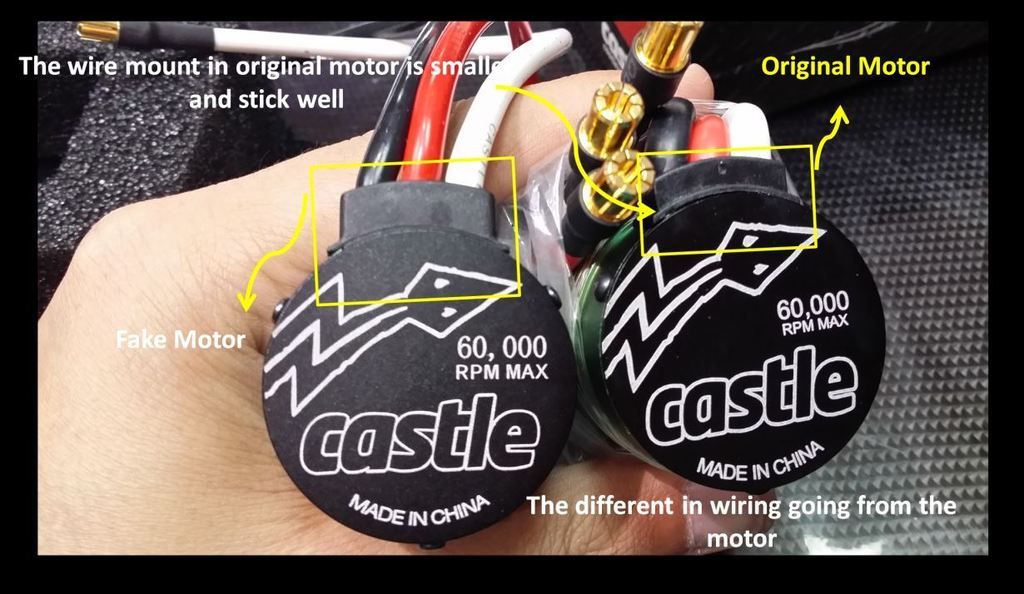

clone a good chinese brand and they jump on you.

notice the engraved parts on the can itself the id numbers they are wrong way up.

larger more bulked wire tunnel ( nothing like original, and same as above)

wire you can get your name printed to wire, you can have whatever you need printed to the outer wire casing

its just a emailed file . theres very obvious differences.

CLONE means an exact copy , problem lays with that term and exact copy, you cant say those hooky motors are.

yes they look like a castle , yes they branded castle, but lots of companys are named castle etc etc.

its just the way it goes, even us military got stung with clone/copied chips n likes

it happens in everything that can be sold, be it your babys powder milk , to state of the art drugs and electronics.

I think the guy with the photo's is just plain wrong. It's just older versions and items split from combo's like the Mamba. Take a look at images for older motors. 2009 here or here, old box design, motor printing upside down and the fonts different to current version, no temp rating on cables, bulked wire tunnel. Take a look at official US Castle dealer http://www.amain.com/, all images are of the so called 'fake' design. Look at the comma position in the 60 , 000 on the new ones.

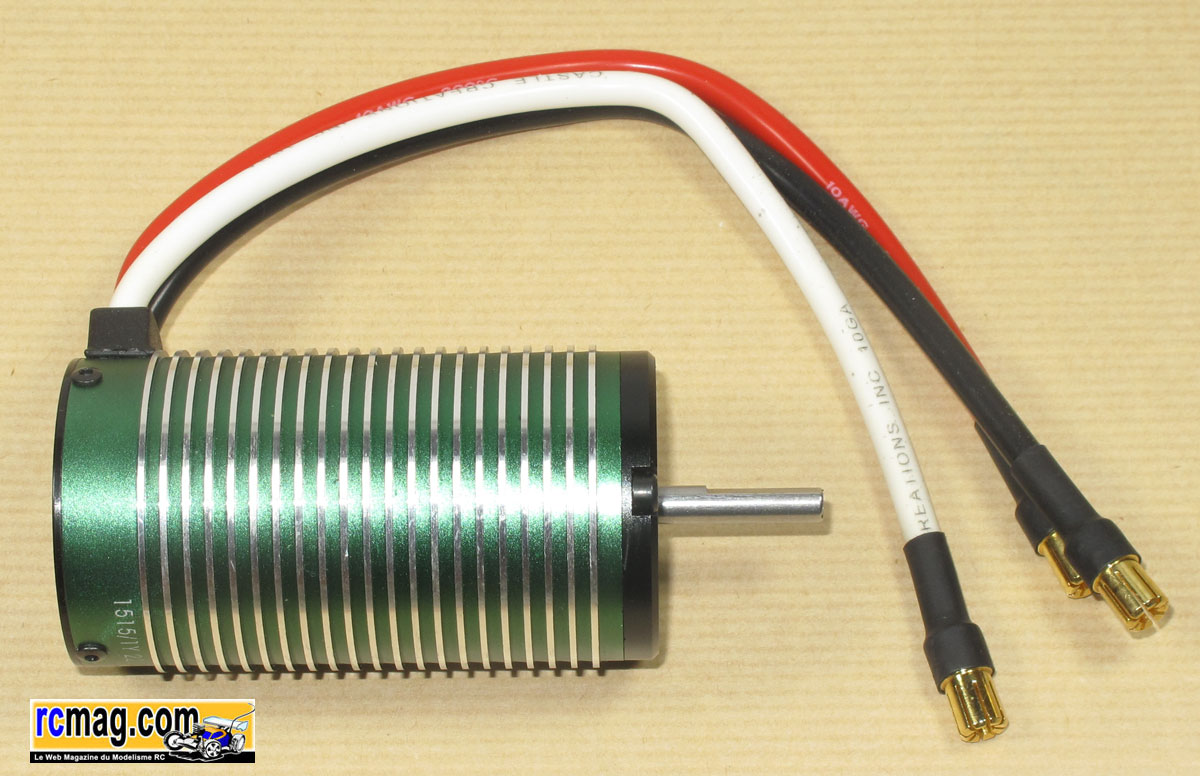

I have a 2200kv 1515 from the HK seller and it's genuine. Printing is correct, correct cables, smaller wire support etc. All as it should be. In fact just checked and it's identical to a 1717 special from a Traxxas X0-1, that can't be a fake. Dude's got paranoia issues.

-

-

I found some white MadMax arms, are they any good vs the RPM ones ?

I've bought them so I can go wild with some Rit Dye.

As good? No, no where near as strong and flexible. But way better than stock. The RPM shock mounts are a problem though, pretty much limited to big bores and no sway bar holes as said. If you want to use anything bigger the MadMax are the best bet, I grabbed a set to go with some Innovative lst shocks if I can ever afford them. White's great for the Rit, dyed mine black and they really are black.

-

Shiny

-

-

I wonder what would cause that, does anyone have the dimensions for it?

Common failure on HPI-105308. Spacer pressed against a metal pin. Loose slipper grinds the pin into plastic. Metal shim on it helps some, but best solution is to make sure your slipper is correctly adjusted and working. A nice grease for drive gears is Lucas Red N' Tacky, stays where you put it, but cleans off easily enough.

-

Fit them together, what ever is left exposed cup wise you fill with solder.

-

-

I learnt the hard way, lefty a nice stain on a ceramic butler sink, she weren't best pleased

-

It doesn't have to be that hot, it's more about the time than higher heat. Too high and you run the risk of warping thinner walls. Stirring every now and again, seems to help keep colour it even as well.

Oh, and one tip, if anyone's never done it before, keep it well away from your kitchen worktops. One drop is all it takes to stain permanently.

-

They recommend adding a little vinegar and 60C constant temp for deepest colours for nylon. And a little washing up liquid helps keeping the colour even, reduces surface tension.

-

Yeah, German firm I think it was.

-

and these have the sway bar mount holes pre drilled. .unlike rpm's...I know were there's a few sets for sell aswell in white only

Do they have any left? Think I might have bought their last ones.

-

Would appear so, rarer than hens teeth now. These were the last one's around, white same as evssv's. They're not as strong as RPM but way better than stock. I like the suspension mounts for lst shocks. The RPM mounts are only really good enough for big bores.They discontinued?

Better than RPM or just similar?

-

-

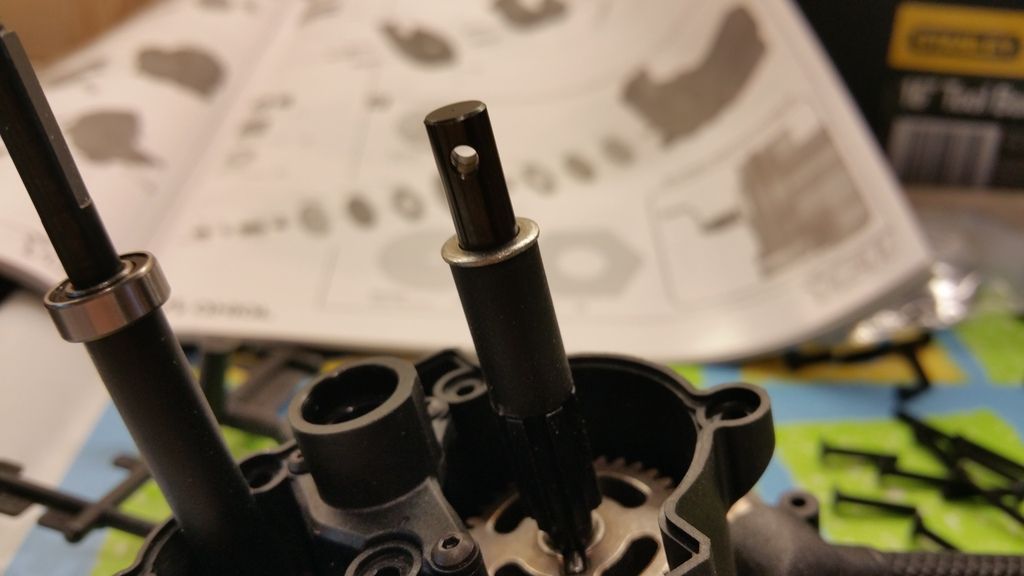

Easily fixed if you get to it before any damage is done, see main thread. Though if I had 4mm play I'd be inclined to make a new shaft spacer/sleeve, it's a bit much for shims.

-

Just working my way through this kit slowly modding here and there, couple of tips.

Don't use the stock bearing's they're horrible.

There's reports of some excessive end float in the drive shaft. 4mm in one case, if the plastic sleeve AX31000 #1 is too short it allows either of the output drive cups to touch the gearbox. Mine was minimal and easily fixed with a 6 (act 5.8mm)x 10 x 0.4mm shim, leave a small 0.2mm end float on the shaft.

Slipper is not much good imo, aluminium will gall up fast and you'll end up cranking it down after a bit. Then expect diff problems. Get a Robinson's Gen3, easy to fit with minimal modding. It's a 64T so helps clear the drive cup, needs a 14T pinion to keep the drive ratio. Really nice, allows fine adjustment of the slipper and it works.

The rear drive shaft twists easily. Find something solid @ 6.25mm rod/dowel etc, make sure it's a good fit and insert it in the hollow shaft, cut it a little long so you can pull it out if needs be. It'll reinforce the walls as they flex and stop them collapsing inwards.

-

First thing swap out the shock ends for some stronger traxxas ones with metal pivot balls.

-

Saw a similar case on another forum. Check the backwards/forwards play, the end float on the drive shaft. One report of 4mm play. Allowed the rear cup, the one with the plastic housing to touch the gearbox and melt and the front cup wearing into the spur gear cover plate.

Checked my part assembled gearbox kit and it needed shimming to get a minimal the end float.

HPI Savage Flux owner club

in Monster RCs

Posted

M4 x 75 cut down to 60mm gives all solid diameter and no threads on the bushes/arms.